In this week’s blog post we highlight our recent Laser Focus World published article on the challenges of new TO-can photonic device manufacturing.

Below we have reproduced the article’s abstract:

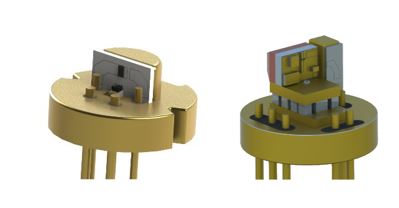

5G networks are the next generation of mobile internet connectivity, and field deployments have started globally. It is driving the vastly increased demand for high-performance advanced optical devices due to meet this demand at an affordable cost. To meet the 5G infrastructure cost target, many new TO-CAN packages used for the high-speed TOSA/ROSA/BOSA/BIDI/Diplexer/Triplexer as well as pump laser components are being developed for low cost pluggable transceivers or EDFAs in 5G network. The TO-CAN packages may reduce the packaging materials cost. However, cost-effective automation tools are needed to support the low-cost volume manufacturing for these complex high-performance TO-CAN, which have multi-chips/dies high-precision attached in a small TO-CAN package by different processes. This article will discuss the challenges of the new TO-Can packages assembly automation. And it also will present an innovative solution for those new generations of TO-Can packaging automation, to respond to the challenges for manufacturing the unique parts that require high-quality and high-efficiency assembly processes for any special TO-Can packages.

Please read previous articles published by MRSI Systems thought leaders in our Insights section of our website.