OUR STORY AND BRAND VALUES

OUR HISTORY

MRSI was founded in Massachusetts in 1984 with the goal of providing automated solutions for dispense and assembly of microelectronic devices. The Company was primarily focused on servicing the hybrid microelectronics industry through the design and manufacturing of precision die bonding and dispensing equipment. Since those early days MRSI have invested over the last 35 years in new products, new services and new offices to meet rapid expansion of our markets. Below we highlight our new products and the journey that took us to the market leader in high precision die bonding.

In 2002 the Company was acquired by the public company Newport Corporation. In 2014 the management executed an MBO from Newport.

MRSI Systems was acquired by Mycronic AB on June 1, 2018. Mycronic AB (publ) is listed on NASDAQ Stockholm, Large Cap: MYCR. It is a Swedish high-tech company engaged in the development, manufacture and marketing of production equipment with high precision and flexibility requirements for the electronics industry.

In late 2021 alongside our investment, in early 2021, in a new Product Demonstration Center in Shenzhen, we established a new legal entity in China – MRSI Automation (Shenzhen) CO., LTD., which will help serve the needs of our local customers including demonstrations and product training.

Since 2018 the company has invested heavily in R&D and has launched several new products to successfully address the volume, flexibility and precision demands of the market.

Our new products, the MRSI-HVM family, the MRSI-H family and the new sub-micron system MRSI-S-HVM have continued the commercial success of our original products MRSI-705 and MRSI-M3.

And we have enjoyed several accolades from the industry including:

- November 2019 Laser Focus World Innovators Award for MRSI-HVM

- January 2020 Infostone 2020 The Most Competitive Optical Communications Product MRSI-S-HVM Submicron Die Bonder

- September 2021 CIOE Silver Award for the MRSI-HVM Die Bonder

- October 2021 Laser Focus World Innovators Award for MRSI-H-TO

- January 2022 Infostone 2021 Outstanding Technology MRSI-H-TO

MRSI is a global Business Unit within Mycronic’s Global Technologies Division.

WHO WE ARE

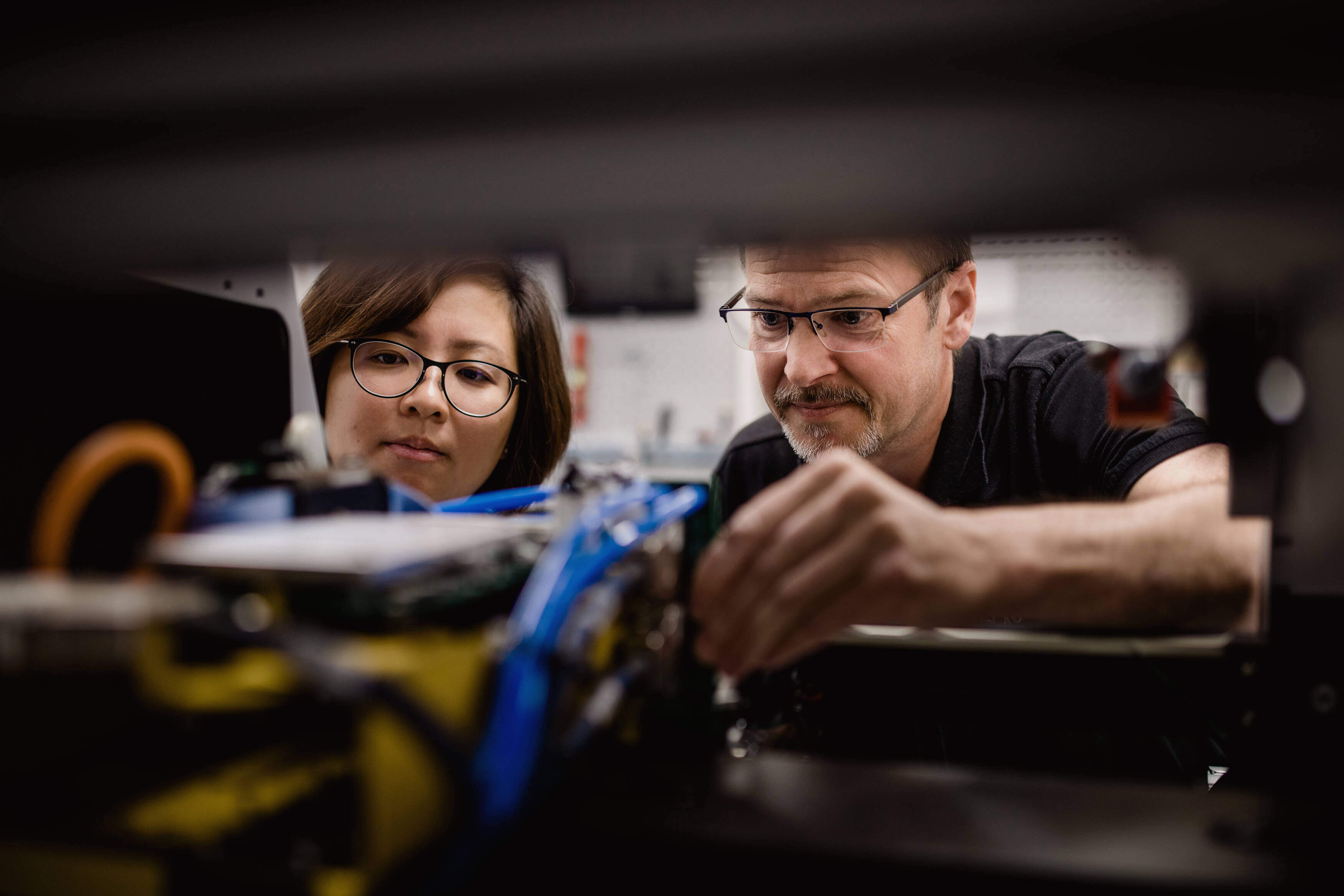

MRSI Systems is a leading manufacturer of fully automated, high-precision, high-speed die bonding and epoxy dispensing systems. We enable customers to optimize the performance of their process including yield, throughput, and uptime by building systems that use our unique expertise. In summary, this includes our proprietary software, proven hardware, deep process knowledge, state-of-the-art manufacturing, and a world-class customer service team. MRSI’s systems are built on common platforms that can be configured to meet specific customer requirements. These platforms are designed to be scalable for R&D prototyping, pilot production and high volume manufacturing. Our solutions deliver the best financial returns in the industry while integrating seamlessly into our customer’s production. Markets include Telecom/Datacom (Data Center), Aerospace & Defense, Medical Devices, Computers and Peripherals, and Industrial. Since 1984, we have been recognized as the standard of the industry, delivering our solutions to leading optoelectronic and microelectronic customers worldwide. Our headquarters is located in a 102,000 square foot building in Tewksbury, MA in the greater Boston area. MRSI’s sales are supported by a global network of direct service and support professionals located in China, Taiwan, Singapore, Korea, Thailand, Malaysia, the Philippines, Israel, Europe, United Kingdom, and the United States. All members of the Mycronic family share a common set of beliefs and guidelines that guide our work.

CREATING VALUE EVERY DAY

Our vision is to be the most trusted partner to the creators of tomorrow’s electronics. And our purpose is to bring tomorrow’s electronics to life.

We strive every day to build an extraordinary workplace, create exceptional value for our customers and have a lasting positive impact on our world. These are the key principles that guide our work.

Take a proactive, customer-centric approach

Partnership. It’s how we’ve defined our customer relationships for over 30 years.

As your partner, we make it our business to know yours and to see things from your perspective. The goal is to understand your specific challenges so well that we don’t just systematically solve them – we anticipate them. Whether it’s keeping up with technological advancements, staying ahead of customer demands, managing inventory, or finding that crucial extra percent of efficiency and productivity.

As our partner, you can count on us to be open and transparent. You can expect us to ask the right questions and to share what we know. And you can trust us to always keep our promises. In short, you can depend on us to put your business first and to work tirelessly to keep you competitive – not just today but over the long term.

Ensure purposeful innovation

As we dream up visions of tomorrow, we do so with our customers’ current and future needs always front of mind. Anticipating their needs drives how we innovate and ensures the creation of sustainable, high-quality solutions with long product life cycles – solutions designed around the people who use them. Our strong patent portfolio is a testament to the success of our purposeful innovation process.

Because game-changing ideas emerge only when you dare to test the limits of what’s possible, we foster a culture of innovation that spans across our entire organization. We seek insights from across functions and a diversity of backgrounds. Then we experiment, learn and adapt our solutions – all to keep our customers profitable and technologically relevant over time.

Have a long-term sustainability mindset

We envision a future where advanced electronics make clean, responsible and profitable progress a reality. This is why we invest in innovations that minimize the environmental impact of ours and our customers’ operations. We also continuously explore and share ideas on sustainable developments, as well as collaborate with our partners to drive change. And we stay ahead of the market in terms of compliance and responsible business practices, bringing our customers tangible business value in the form of energy-efficiency and a reduced carbon footprint.

Because we believe that sustainability comes from within, we nurture a strong internal culture of empowerment. We actively promote an inclusive and healthy work environment by embracing diversity and showing compassion for our colleagues. We will never tolerate illegal and unethical business practices, and we encourage all employees to stand up and speak out should they ever encounter them.

For the sake of our environment, the well-being of society and the continuing success of our customers, there can be no compromise. We will continue to apply our long-term sustainability mindset to secure the seamless delivery of tomorrow’s electronics.

Set the standard for a dynamic, people-centric culture

At Mycronic, we love what we do. And we take every opportunity to enthusiastically collaborate with our customers and colleagues. Because to us, every colleague has a unique insight to share and every customer a unique idea of what’s valuable.

We insist on an open and transparent culture that promotes personal growth and embraces diversity. An environment that nurtures new ideas and encourages innovations that positively impact businesses, society and the planet. As we co-develop new solutions with our customers, we share responsibility for bringing new ideas to life. And if we discover a better path, we act on it and are accountable for the results.