5G infrastructure will require ultra-high bandwidth, latency up to 1 ms, and highly reliable connectivity. In addition, RF architectures need to be scalable, efficient, and extremely compact. This requires densification not only at the macro level with the installation of more base stations but also high-power density at the device level.

5G macro stations will be dominated by a large-scale array antenna with 64 channels, and the power amplifier demand for a single base station will be as high as 192 channels (196 units power amplifier devices). The demand for the RF PA devices in 5G networks is a few times higher in unit volume compared to that in 4G networks.

The 5G devices are more cost sensitive than ever, which needs higher speed manufacturing equipment to reduce cost. Die bonding is an essential element in the manufacturing of these devices. MRSI-705 flexible die bonder high-volume configuration was recently introduced to target RF power amplifiers and microwave applications, as well as some photonics device applications.

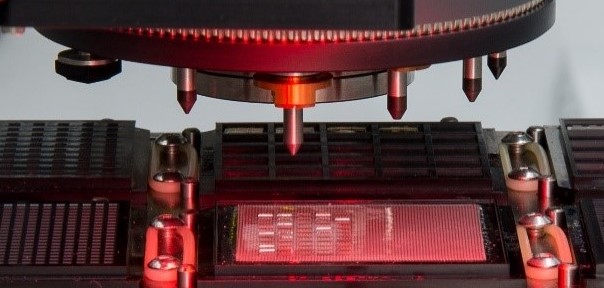

An optional MRSI-705 Turret configuration significantly increases the output of the machine without sacrificing flexibility. This configuration features an “on-the-fly” auto tool changer with up to 12 tools integrated on the bonding head for zero-time tool change. This leads to increased machine efficiency, higher output, and lower manufacturing costs, and hence higher ROI for the customers. The system has a large work area for improved flexibility to build complex packages with multiple dies. Fewer pieces of equipment are needed, and higher utilization can be achieved for complex products containing chips of different sizes, and processes that require both eutectic bonding and epoxy stamping or dispensing. The production efficiency of this turret configuration for typical 5G RF PA devices is more than double that of the standard MRSI-705. For complex Tx/Rx microwave devices, the production efficiency gain will be even higher.