In the November/December 2023 issue of Chip Scale Review, MRSI delves into the fascinating world of automotive light detection and ranging (LiDAR) technology. This article explores the parallels and distinctions between LiDAR and optical transceivers.

Here is an excerpt from the article:

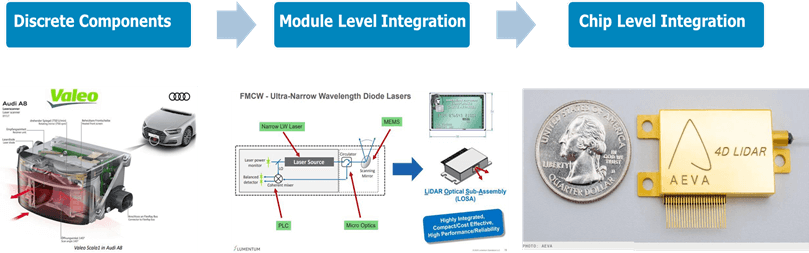

“With the advancement of new technologies, we find that automotive LiDAR imaging technology has evolved from mechanically-scanned LiDAR to hybrid solid-state LiDAR, and then to solid-state LiDAR. The packaging of automotive LiDAR evolved from discrete components to module-level integration, and even chip-level integration (see Figure 1). The market is trending towards highly-integrated, thinner and cheaper products [1-4]. Consequently, higher accuracy assembly is required to manufacture the photonics devices. Automotive LiDAR has a similar photonics device assembly process to that of the optical transceivers, and the assembly accuracy and other requirements are also similar. Depending on the different laser package designs, from 5μm to 0.5μm is the typical high-accuracy requirement for laser die; other parts, however, may have less critical accuracy requirements. In general, most edge-emitting laser dice are attached with a eutectic process (some may use an epoxy process); VCSEL laser dice are usually attached with an epoxy process, and an optical lens with ultraviolet (UV) epoxy plus in situ curing.”

Contact us to learn more about our assembly solutions.

Reference:

- Limin Zhou, “Flexible high-volume die bonding solution targets modern photonics manufacturing” Laser Focus World, July 2020

- Philip E. Ross, “Aeva Unveils Lidar on a Chip: Aeva says its high-performance lidar will sell for less than US $500; VW is buying it”, IEEE Spectrum, 11, Dec, 2019

- Lumentum White Paper “Practical Solutions for Enhancing Autonomous Vehicle Safety Using LiDAR-based 3D Sensing”, 2020

- Valeo Scala Laser Scanner Report, System Plus consulting 2019.