MRSI’s latest article in the July 2020 issue of Laser Focus World highlights a flexible die bonding solution for modern photonics manufacturing. Here is an excerpt from the article:

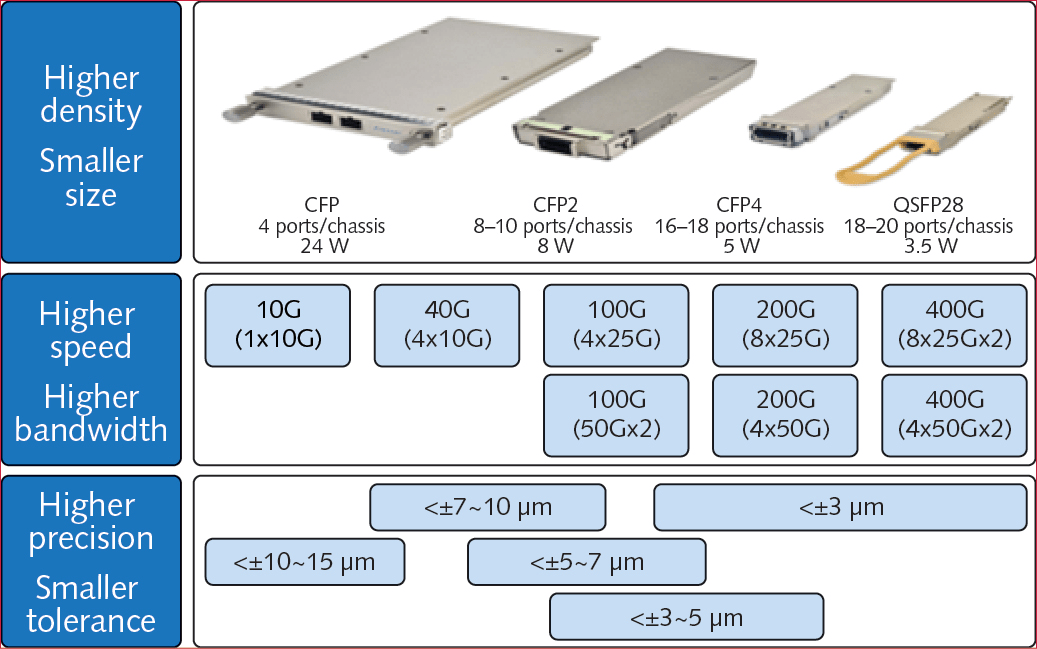

One of the greatest challenges in the manufacturing of these devices is the ability to successfully deploy flexible die bonding solutions to meet the wide range of needs for high-volume production with high post-bonding accuracy and great long-term stability. Historically, the post-bonding accuracy has been evolving from 10–15 µm to 7–10 µm, to 5–7 µm for each previous generation of photonic devices. The newest generations of high-performance photonic devices require a <3 µm post-bonding accuracy, without sacrificing high throughput or high flexibility for a high mix of product types in high-volume manufacturing.

The traditional high-volume semiconductor equipment may have high accuracy and high speed, but does not have the level of flexibility required for photonic devices. There also have been some die bonders specifically designed for photonics manufacturing with accuracy and flexibility or speed, but not all these criteria. Here, we introduce the industry-first field-proven post-bonding accuracy of 3 µm or better on a 1.5 µm high-speed and highly flexible die bonder platform (MRSI-HVM) for high-volume and high-mix photonics manufacturing.

Read the full Laser Focus World Article.

Contact MRSI to learn more about our die bonding solutions for modern photonics manufacturing.