ULTIMATE ACCURACY

MRSI-HVM1

For detailed Data Sheets please contact Sales.

MRSI-HVM1

HIGH SPEED, FLEXIBLE, ULTRA PRECISION 1 MICRON FLIP-CHIP DIE BONDER FOR HIGH VOLUME MANUFACTURING

Advanced ultra precision solution for flexibility and volume production – 1 Micron Accuracy

Benefits of MRSI-HVM1

MRSI’s die bonding solutions help our customers to enable just-in-time supply and fast-pace innovations of critical components for high-growth market segments. The MRSI-HVM1 is developed from our popular MRSI-HVM platform, further improving accuracy to 1 micron level.

This product inherits the MRSI tradition of combining accuracy, speed and flexibility to reduce NPI cost, improve production agility and hence increase ROI for customers. It also comes with MRSI’s long proven product reliability and global customer support.

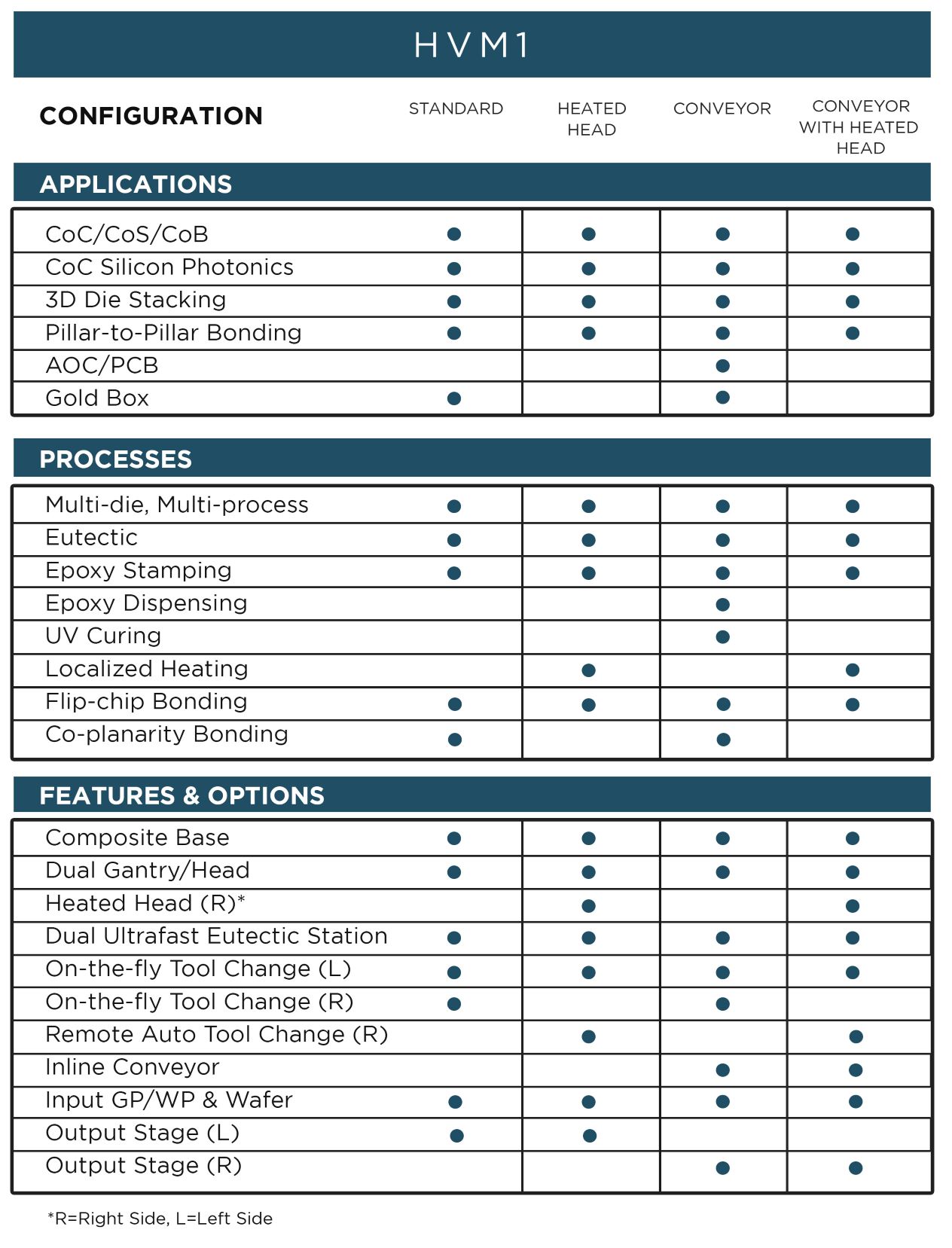

The MRSI-HVM1 is designed for specific applications including Chip-on-Carrier (CoC), Chip-on-Submount (CoS), and Chip-on-Baseplate (CoB) assembly using eutectic and/or epoxy stamping die bonding.

The conveyor version – the MRSI-HVM1 with conveyor is equipped with inline conveyor for single fixture or multiple cassette inputs that can automatically transport large forms of carriers of the dies for Active Optical Cables (AOC) or similar chip-on-printed circuit board (PCB) applications, gold-box packaging, and CoC in fixture. The process choices include eutectic, epoxy stamping, UV epoxy dispensing, and in-situ UV curing.

The heated head version includes a heated head on the right side while the left side still has the same head as a typical MRSI-HVM1. The localized top heating at a fixed temperature or with pulsed heating is specially designed for eutectic bonding of multiple dies onto a common carrier without reflowing the neighboring solder pads.