Dr. Limin Zhou, Senior Director Strategic Marketing, MRSI Systems

Rapid Growth of LiDAR Market

LiDAR is an integrated optical detection and measurement system. Compared with typical radar, LiDAR can provide high-resolution distance, velocity, and geometric images, which were originally used in the military field. LiDAR will be primarily used by high-end advanced driver-assistance systems (ADAS) and self-driving cars. Self-driving cars are an important force which is driving the LiDAR industry. This new technology has great significance for improving traffic efficiency, saving resources, reducing pollution and lowering accident rates.

Some automakers have announced or planned to integrate LiDAR technology into future vehicles. At present, the most active players in the field of autonomous driving are internet enterprise companies. These internet enterprise companies are leading the industry in the development of technology ahead of the traditional car companies.

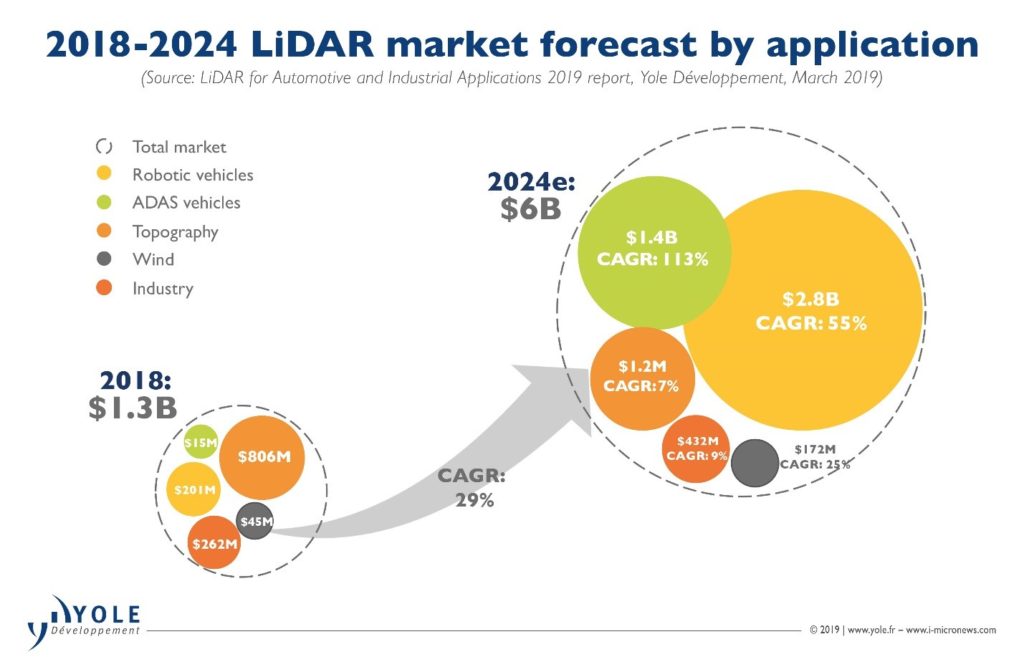

Source: LiDAR for Automotive and Industrial Applications 2019, Yole Development, March 2019

Fast Innovation of LiDAR Technology

In order for automakers to achieve ambitious goals of producing and deploying autonomous driving vehicles at scale, they need to acquire high-performance, low-cost LiDAR solutions. The requirements include product performance, cost, reliability, manufacturability, and other key indicators:

Performance: 200~300 meters range, 0.1~0.2 degrees of spatial resolution

Cost: volume production to hit hundreds of dollars pricing target

Reliability: automotive grade to match the lifespan of vehicle systems

Manufacturability: design for highly automated manufacturing

Challenges of LiDAR Applications

Currently, there are many new technologies and approaches for LiDAR development, but many challenges exist in LiDAR applications. The current technology landscape for LiDAR has few options that can meet the performance, cost, reliability, and manufacturability requirements for automotive applications. A cost-effective LiDAR manufacturing solution is expected, then a fully automatic assembly solution will support the acceleration of the LiDAR applications from low volume to high volume. Moreover, high precision is also needed through automation for high density, small size packaging. Automatic production can provide a high level of consistency and reliability for product quality to meet Automotive LiDAR applications requirements. Automation technology is required to ensure high performance and quality at the initial stage of design.

Flexible Automation Solutions for LiDAR

LiDAR Ecosystem and Process Automation

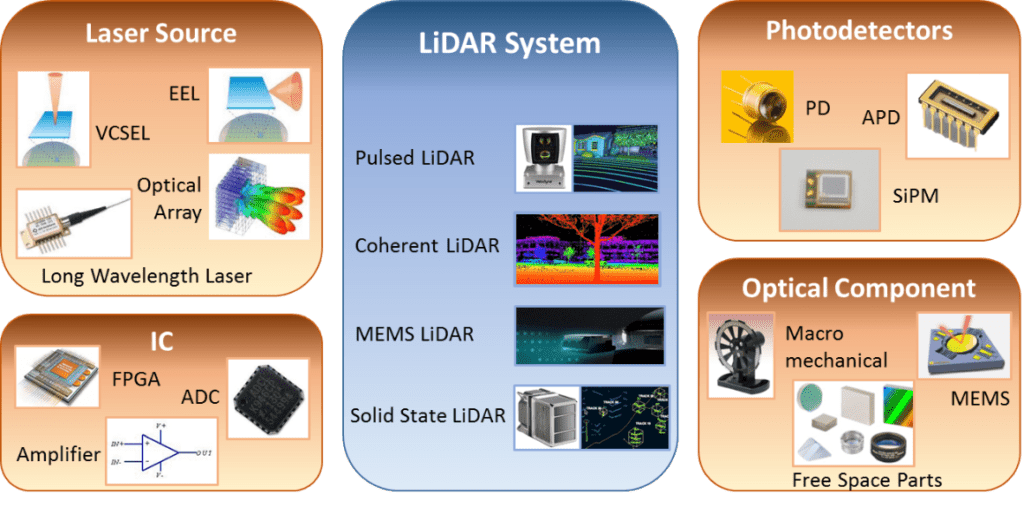

Both traditional and future LiDAR products are very similar to optical communication devices in terms of hardware, which also require core components such as a laser light source, photodetector, an optical element, and IC chips. However, a LiDAR product uses more of these components and requires more complex manufacturing processes. The following figure shows the LiDAR ecosystem for vehicles.

Die Bonding Process Requirements of LiDAR Applications

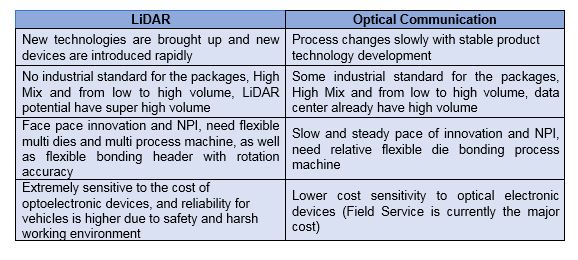

With the rapid development of the optoelectronics industry, the demands of developing a variety of sustainable, high-precision, low-cost, optical engine assembly and packaging protocols has increased significantly. This also includes critical automotive LiDAR application requirements. By analyzing these different requirements, MRSI’s solutions can cover all of the aspects of LiDAR product assembly. For both traditional and future LiDAR hardware components and hardware integrations, the process technologies are similar to Optical Communication devices but have some different features.

Based on the LiDAR ecosystem and technologies, there are some basic requirements of the die bonding process from these aspects:

- For multiple light sources in the LiDAR ecosystem, the die bonder should have a eutectic stage, epoxy dispensing and UV curing features which enables multiple processes in the same machine for ultimate flexibility.

- For cost sensitivity, customers need increasing return-on-investment (ROI) with one die-bonder instead of several machines. Customers require that the production line has the ability to scale-up rapidly with new design changes or continue with existing designs mitigating the need for additional equipment.

- For high volume, customers need high throughput by designed-in parallel processing. Customers need to handle multiple-die with fast cycle time reducing factory downtime.

- For new technologies which are introduced rapidly, high placement accuracy will support innovation of future designs and creates high yields reducing the cost of poor quality.

To a certain degree, these challenges are similar to data center applications.1

MRSI Systems – “One Stop Shop” Fully Automated Die Bonding Solutions

MRSI fully automatic die bonding platform has unique product features which meet the criteria of flexibility, speed, and precision. MRSI can meet the LiDAR application die bonding process requirements as we have already successfully demonstrated for data center applications which have similar challenges.

- The capability to process multiple die designs with multiple processes for ultimate flexibility. The MRSI die bonder also has a eutectic stage, epoxy dispensing and UV curing features which enables multiple processes in the same machine for added flexibility compared with competing solutions that can offer the capability but need hardware upgrades or dedicated set-ups.

- Increase return-on-investment (ROI) with one die-bonder instead of several machines. When comparing the unique die bonder features to competing solutions, customers will realize a high ROI and a competitive advantage because their production line has the flexibility to scale-up rapidly on new design changes or continue with existing designs mitigating the need for additional equipment.

- High throughput by designed-in parallel processing. MRSI die bonders have an integrated turret to hold up to 12 tips which benefit customers who need to handle multiple-die with fast cycle time reducing the need for factory downtime and competitors have slow tool changes for their die bonding systems and other machines which reduces factory throughput.

- High placement accuracy of ±3 µm @ 3 sigma with 360˚ high accuracy rotation, supporting innovation of future designs and creates high yields reducing the cost of poor quality.

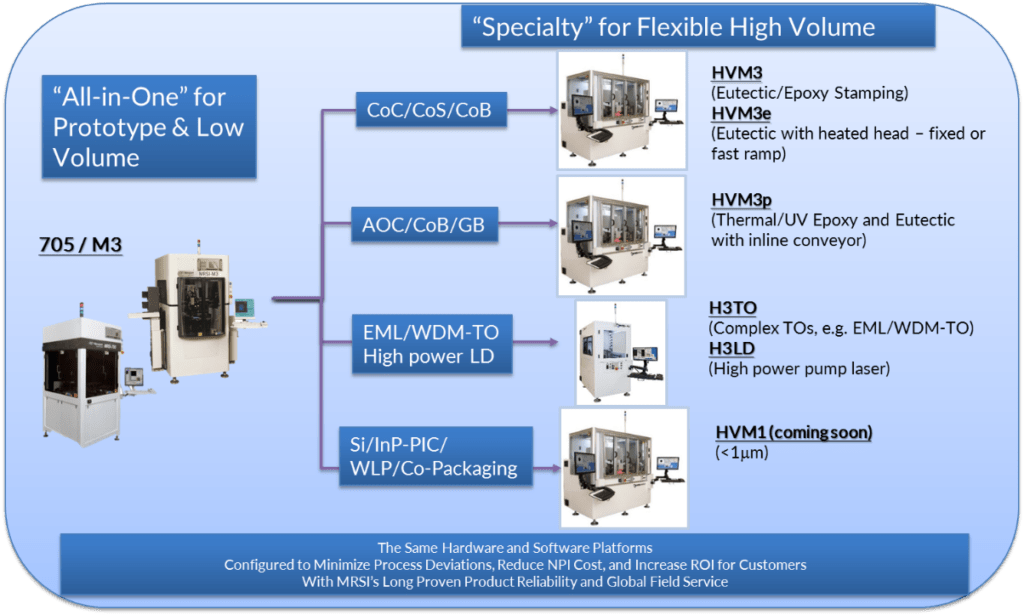

MRSI’s systems are built on common platforms that can be configured to meet specific die bonding requirements for LiDAR applications. These platforms are designed to be scalable for R&D prototyping, pilot production, and high volume manufacturing. The following figure shows MRSI’s “one-stop-shop” die bonding solutions. The equipment with various configurations will be suitable for the requirements of various die bonding processes from LiDAR prototype samples development to mass production.

MRSI flexible automation solutions deliver the best financial rewards among the industry while integrating seamlessly into our customer’s production. We enable customers to optimize the performance of their process including yield, throughput, and uptime by building systems that use our unique technology. MRSI delivers “one stop shop” die bonding solutions to leading optoelectronic and microelectronic customers worldwide. The flexible fully automatic die bonding solutions will be the best solution to accelerate LiDAR industry mass production for the autonomous driving vehicles.

1 Laser Focus World August 2018 “Challenges for photonics manufacturing in the new data center era.” Yi Qian, MRSI Systems