Designed for high-volume manufacturing of advanced photonics and RF / Microwave devices the MRSI-H-LD 1.5 micron die bonder delivers industry-leading speed without sacrificing ultra-high precision and superior flexibility. The system is capable of building of Chip-on-Carrier (CoC), Chip-on-Submount (CoS), Chip-on-Baseplate (CoB), passive lens attachment, and box packaging for customer’s products such as high–power laser diodes (HPLDs), Optical communication components, and RF power amplifiers, Microwave devices, as well as photonics sensors and silicon photonics components.

Additional applications include passive lens attachment and box packaging. For the PCB level of products such as active optical cables (AOC) and onboard Optical (OBO), the final lens attachment can be done passively with high–accuracy. MRSI’s high–precision die bonders are also widely used in different kinds of gold–box packaging products by applying eutectic and epoxy processes.

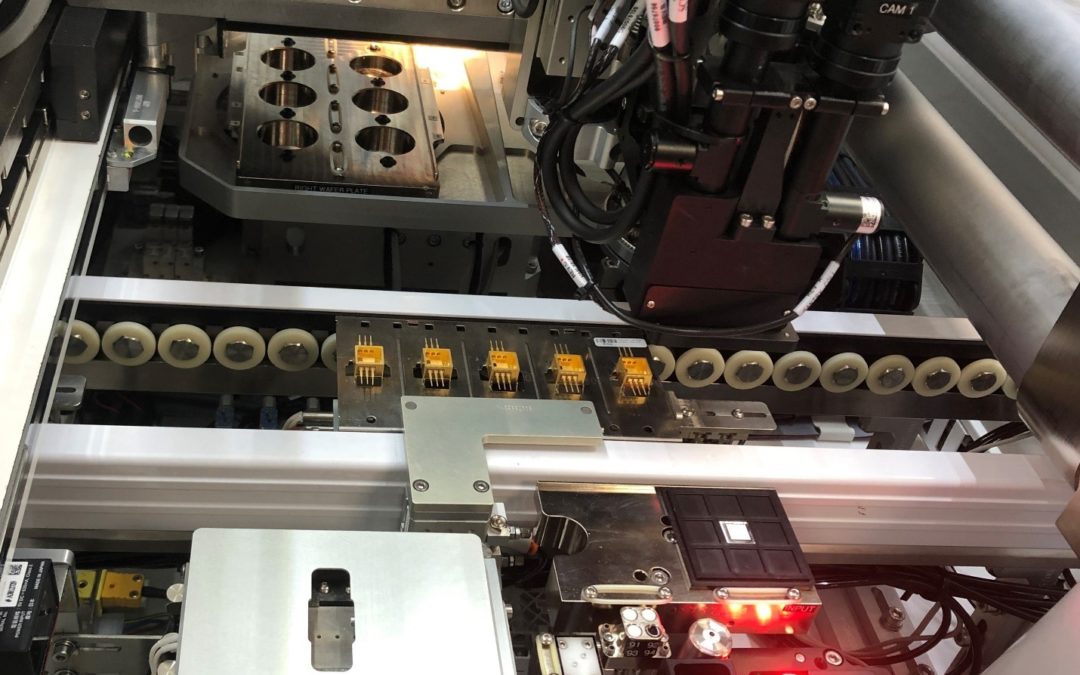

MRSI’s latest hardware and software innovations consist of a gantry-mounted pick-and-place head. With a slightly different configuration, the MRSI-H-LD can be optimized for multiple applications that bond large die for high-power laser diodes, industrial lasers, optical fiber amplifiers, power amplifiers, lighting, and sensors. The uniformity of the joint material thickness is optimized by the self-leveling tools, and the void percentage is minimized by extremely uniform heating with the specially designed eutectic stage. Both factors help our customers by improving product yield and field reliability.

This innovative system can be configured with an ultrafast-ramp eutectic station, parallel material handling, and dual bonding stages. Also, the unique capability of handling and bonding multiple-die of different sizes and geometry without changeover within one machine benefits customers by providing the best-in-class throughput for capacity expansion and unmatched flexibility for production all in one solution.

The pick-and-place head configured with a built–in heated head enables high–accuracy for advanced high-density product packaging applications is an additional configuration. Other configurable options include wafer input, conveyor and load/unload units for higher volume production to increase throughput. The machine in-line function can achieve fully automatic production for our customers.

Contact MRSI to learn more about our assembly solutions.