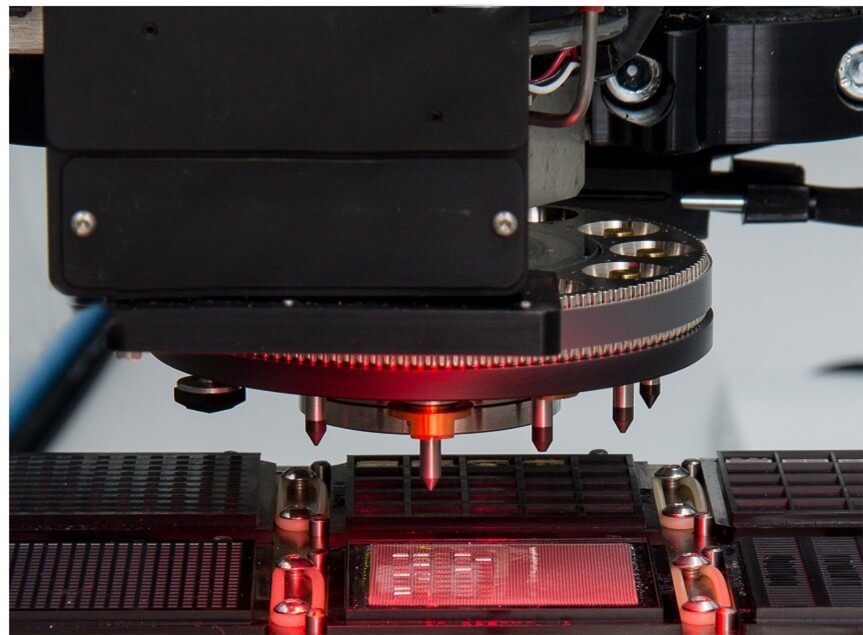

12 tool positions turret offered in MRSI’s 705, H-LD, and HVM systems

In the world of chip packaging and advanced die bonding, the pursuit of efficiency, accuracy, and productivity is a continuous endeavor. MRSI’s die bonding systems offer a cutting-edge automatic tool changing turret solution that streamlines die attach processes enabling ZERO tool changeover time and higher productivity.

- Automatic Tool Changing Turret

The automatic tool changing turret is an integral feature for advanced heterogeneous packaging and die attach, enabling to change the tool on-the-fly, saving precious seconds of processing time. The automatic tool changing turret automatically swaps tools without sacrificing accuracy or losing calibration.

- Advantages

1. Enhanced Efficiency: one of the most important benefits of the turret is the significant improvement in production efficiency. Having the turret die bonding operation reduces cycle time.

2. Flexibility and Adaptability: With the ability to hold up to 12 tools, the turret allows customers to handle diverse die bonding processes within the system, making it easier to adapt to changing production needs.

MRSI’s 705, M3, H-LD, and HVM systems offer an automatic tool changing turret option to significantly reduce cycle time. This feature delivers an “on-the-fly” tool changer with up to 12 tools, and with zero tool changeover downtime. This leads to increased flexibility, higher output, and lower manufacturing costs. Applications include complex products with multiple dice and processes, which can significantly improve equipment efficiency.